|

| February 19, 2013 | Volume 09 Issue 07 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Thanks in part to FUTEK sensors, Curiosity finally drills into Martian terrain

At the center of this image from NASA's Curiosity rover is the hole in a rock where the rover conducted its first sample drilling on Mars Feb. 8, 2013 (Sol 182), Curiosity's 182nd Martian day of operations. Several prep activities with the drill preceded the operation, including a test that produced the shallower hole on the right two days earlier. [Image credit: NASA/JPL-Caltech/MSSS]

Since its landing in August, NASA JPL's Mars Rover Curiosity has yet to utilize its drilling arm to full capacity. However, that all changed on February 8, 2013, when Curiosity officially bore its first hole into the Martian surface.

Seen as the rover's most complex device, the robotic drilling arm penetrated what is identified as a "flat, veiny rock" to collect its first samples. This collection marks the first sampling of any rover on Mars.

Helping to ensure the success of this drilling mission, FUTEK Advanced Sensor Technology Inc. designed and developed two customized sensors for this exact moment.

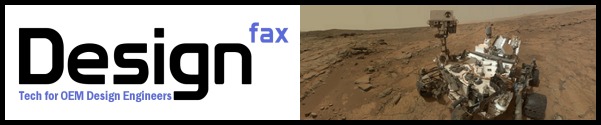

FUTEK was commissioned by NASA to develop and manufacture a cryogenic donut load cell that sits within the drilling mechanism on the rover. This special dual-bridge Thru-Hole Load Cell measures the forces of the drill bit as it bores into the Martian terrain. The sensor measures the forces at a higher level of accuracy and resolution than a current-controlled motor drive system could achieve. The inclusion of a dual bridge was necessary to provide redundancy in the system, reducing the risk of the system becoming inoperable in the extreme conditions.

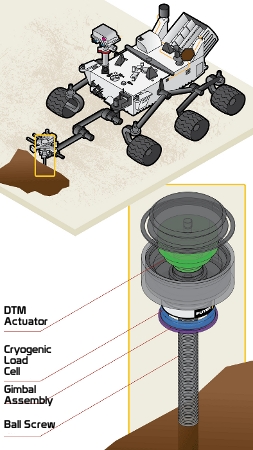

FUTEK was also commissioned by NASA JPL to develop a space-/flight-qualified cryogenic three-component sensor. With capabilities of measuring torque and force, this Multi-Axial Sensor operates within the rover's robotic arm. As the arm maneuvers, the sensor provides feedback to the operating device to identify the levels of torsion and force applied to the arm. The necessity of this multi-axial sensor is to alert the rover if over-exertion on the arm occurs.

An animated set of three images from NASA's Curiosity rover shows the rover's drill in action on Feb. 8, 2013. [Image credit: NASA/JPL-Caltech]

These precision instruments contributed to the drilling of the 0.63-in.-wide, 2.5-in.-deep hole in the Martian bedrock. From topographical surveys and imaging, NASA JPL scientists concluded that this particular location showed evidence of water/moisture saturation.

Now, FUTEK and the world await Curiosity's analysis of the rock sample to confirm this theory.

Ground controllers will guide Curiosity through multiple stages of investigation using the rover's Collection and Handling for In-Situ Martian Rock Analysis (CHIMRA) device.

Stay tuned ...

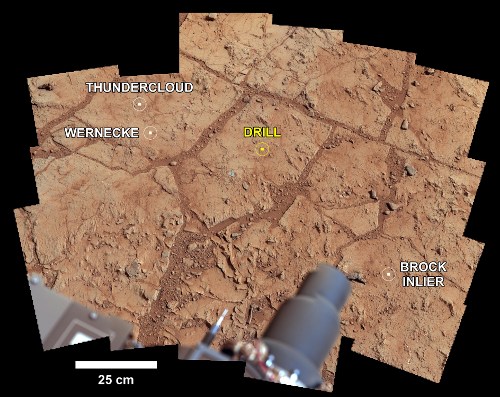

NASA's Mars rover Curiosity used its Mast Camera (Mastcam) to take the images combined into this mosaic of the drill area, called "John Klein." Shown on this annotated mosaic are the four targets that were considered for drilling. The label "Drill" indicates where the rover ultimately performed its first sample drilling. [Image credit: NASA/JPL-Caltech/MSSS]

Learn more about FUTEK load cells here.

Learn more about FUTEK multi-axial sensors here.

Source: FUTEK Advanced Sensor Technology

Follow Curiosity's progress and milestones at http://mars.jpl.nasa.gov/msl/news/whatsnew/.

Published February 2013

Rate this article

View our terms of use and privacy policy